- Address: 247 LIG 2 Lakshmikanth nagar 1st hebbal, Mysuru-570017

- Address: 247 LIG 2 Lakshmikanth nagar 1st hebbal, Mysuru-570017

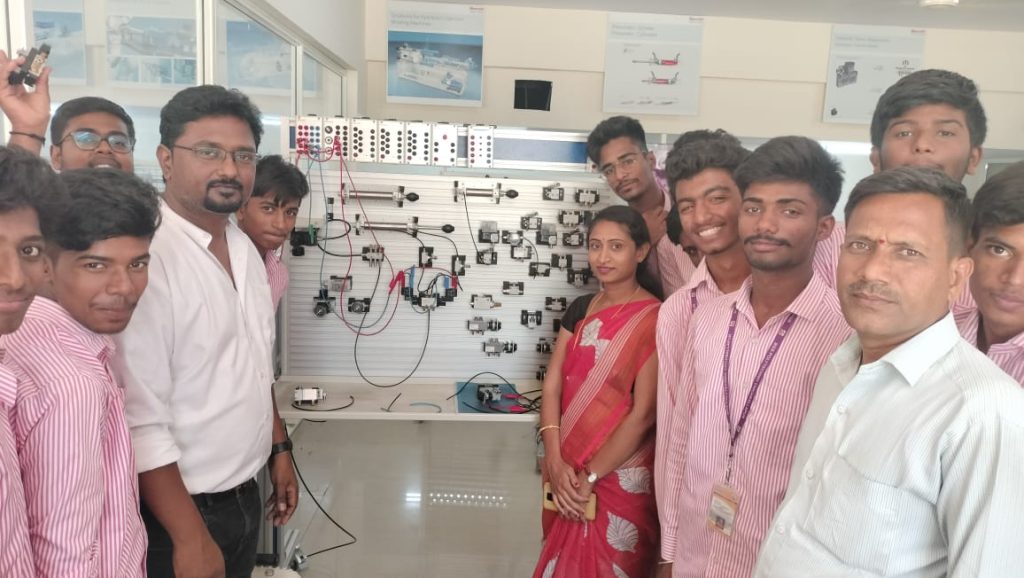

Industrial Pneumatics Training

Industrial Pneumatics Training

Duration: 40hours

Course Introduction:

iRobo Automation Pvt Ltd, a renowned provider of automation solutions, is organizing a practical and comprehensive hands-on training program on Industrial Pneumatics. This program is specifically designed to cater to the needs of both students and corporate employees who are seeking to gain practical knowledge and skills in the field of pneumatic automation.The training program conducted by iRobo Automation Pvt Ltd offers a unique opportunity for participants to immerse themselves in the world of Industrial Pneumatics. The program is tailored to two distinct groups: students who want to establish a solid foundation in pneumatic automation and corporate employees who are looking to expand their expertise or upskill in this area.The hands-on training sessions provide participants with a dynamic learning environment where they can actively engage with pneumatic systems and equipment commonly used in industrial applications. The curriculum covers a wide range of topics, including the basic principles of pneumatics, pneumatic components and circuits, system design and troubleshooting techniques, and safety considerations.Students attending the training program will benefit from a structured learning experience that combines theoretical knowledge with practical application. By gaining hands-on experience with pneumatic systems, students can bridge the gap between theory and practice, enabling them to better understand the concepts and prepare themselves for future careers in automation and engineering.For corporate employees, the training program serves as an opportunity to enhance their professional skills and expand their knowledge in the field of Industrial Pneumatics. By acquiring a deeper understanding of pneumatic systems, participants can contribute more effectively to their organizations’ operations, maintenance, and troubleshooting activities. This training can lead to increased efficiency, reduced downtime, and improved safety in industrial settings.The training program is led by experienced professionals with extensive knowledge in pneumatics and automation. These trainers provide guidance, support, and mentorship to participants, ensuring a valuable and enriching learning experience. The hands-on nature of the training allows participants to apply theoretical concepts in practical scenarios, fostering the development of practical skills necessary for working with pneumatic systems.iRobo Automation Pvt Ltd’s hands-on training on Industrial Pneumatics is a valuable platform for students and corporate employees to enhance their understanding of this vital aspect of automation. By participating in this program, individuals can gain the skills and knowledge necessary to excel in the field of pneumatics, contributing to the overall growth and success of their respective industries.

Enquiry Now!

Course Contents:

- Introduction to Industrial Pneumatics

- Basics of pneumatics and its advantages in industrial applications

- Overview of pneumatic components and systems

- Pneumatic Components and Circuit Design

- Understanding pneumatic components (compressors, actuators, valves, etc.)

- Different types of pneumatic circuits and their applications

- Circuit design considerations for efficient and reliable pneumatic systems

- Pneumatic Actuators and Control Systems

- Types and operation of pneumatic actuators (cylinders, rotary actuators, etc.)

- Control methods for pneumatic systems (solenoid valves, pressure regulators, etc.)

- Closed-loop control and feedback systems in pneumatics

- Pneumatic System Design and Analysis

- System requirements and specifications for pneumatic applications

- Design considerations for optimal performance and energy efficiency

- Analyzing and optimizing pneumatic circuits

- Pneumatic Valves and Controls

- Types and functions of pneumatic valves (directional, flow control, pressure relief, etc.)

- Valve symbols and specifications

- Control techniques and applications of pneumatic valves

- Pneumatic Circuit Troubleshooting and Maintenance

- Common issues and faults in pneumatic systems

- Troubleshooting techniques and problem-solving approaches

- Preventive maintenance practices for pneumatic systems

- Pneumatic System Integration and Control Interfaces

- Interfacing pneumatic systems with other automation technologies

- PLC (Programmable Logic Controller) integration for pneumatic control

- Communication protocols and networking in pneumatic systems

- Safety Considerations in Pneumatics

- Understanding and managing pneumatic system hazards

- Safety guidelines for working with pneumatic equipment

- Emergency procedures and protocols

- Practical Hands-on Exercises

- Hands-on experience with pneumatic components and systems

- Assembly, disassembly, and maintenance of pneumatic circuits

- Troubleshooting and problem-solving exercises

- Industry Applications and Case Studies

- Real-life examples of pneumatic systems in various industries

- Case studies on successful pneumatic system implementations

- Practical application scenarios and project discussions

- Industry Best Practices and Emerging Trends

- Current trends and advancements in industrial pneumatics

- Best practices for efficient and sustainable pneumatic systems